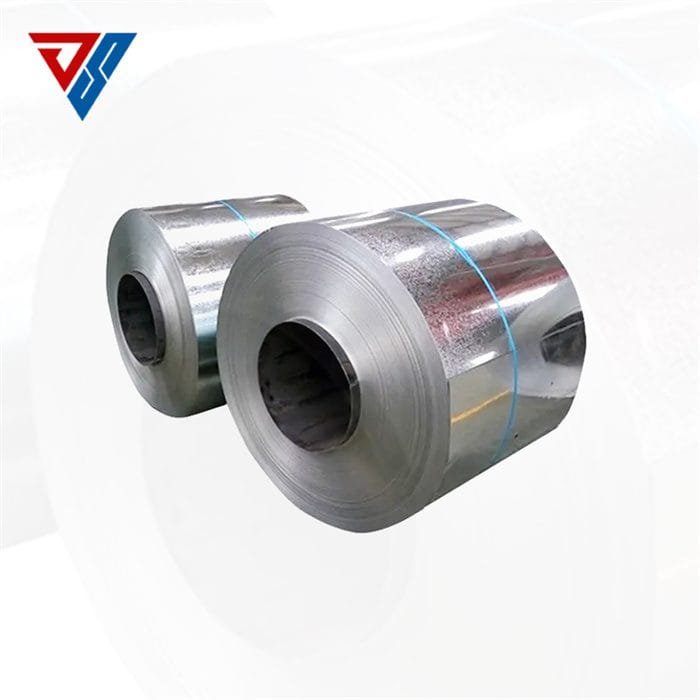

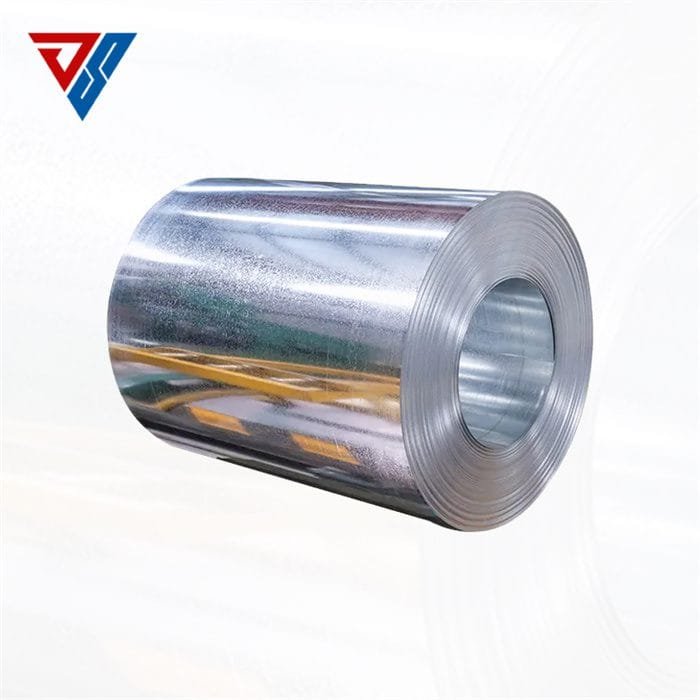

Product Introduction

Galvanized coil is a kind of steel material coated with zinc. Galvanized roll is the predecessor of galvanized sheet, the use of equipment to cut the galvanized roll into a board, with forklift or crane to put the galvanized roll on the shelf and then through the equipment transmission, flattening, cutting. The width is the standard width of one meter, one meter twenty-five, one meter fifty-three, the length is arbitrary.

| اسم | Galvanized coil /roll | ||

| معيار | ASTM A775M/A792, JIS G3322,AISI, DIN, GB | ||

| درجة | SGLCC | DX51D+AZ | S250GD+AZ |

| SGLCD | DX52D+AZ | S280GD+AZ | |

| SGLC440 | DX53D+AZ | S320GD+AZ | |

| SGLC570 | DX54D+AZ | S350GD+AZ | |

| ASTMA792 | S550GD+AZ | ||

| سماكة | 0.12mm-4mm | ||

| عرض | 600mm~1500mm | ||

| تسامح | Thickness+/-0.01mm Width +/-2mm | ||

| AZ Coating | 30~275gsm | ||

| مشبك | zero spangle, regular spangle or normal spangle | ||

| معالجة السطح | Galvalume, skin passed or non-skin passed chromed / skin pass/ oiled/slightly oiled/ dry/ anti-fingerprint | ||

| وزن الملف | 3-8 tons or as client requirement. | ||

| صلابة | Soft &Half Hard & Full Hard or As Per Customer Request | ||

| التعبئة والتغليف | Standard export package (Plastic film in the first layer, second layer is Kraft paper. Third layer is galvanized sheet) | ||

Product Application

Galvanized coil products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commercial industries.

The construction industry is mainly used for the manufacture of anti-corrosion industrial and civil building roof panels, roof grilles, etc.

The light industry uses it to manufacture household appliance shells, civil chimneys, kitchen utensils, etc., and the automotive industry is mainly used to manufacture corrosion-resistant parts of cars.

Agriculture, animal husbandry and fisheries are mainly used as food storage and transportation, meat and aquatic products frozen processing equipment;

Commercial mainly used as materials storage and transportation, packaging tools, etc.

Project Case

تكنولوجيا المعالجة الإضافية

تغليف المنتج

تغليف المنتج